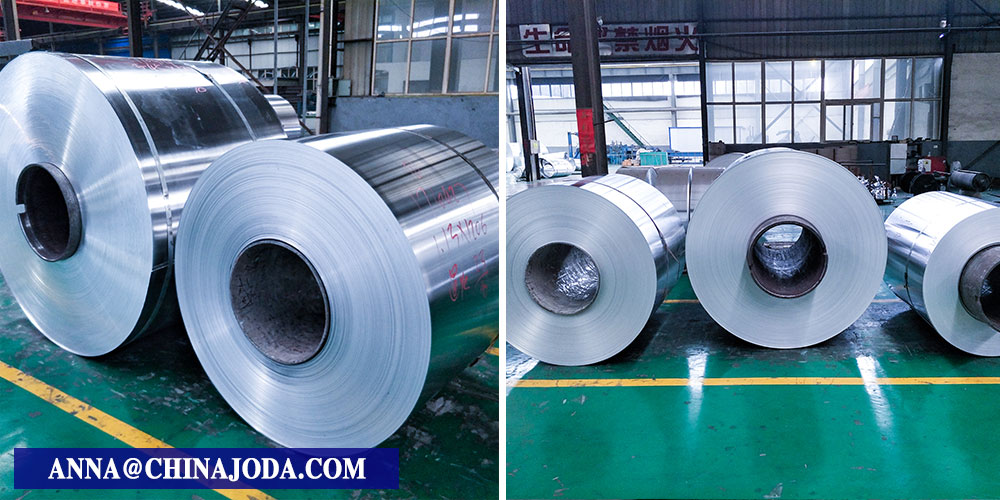

Aluminum Coils/Roll

Temper: O/H12/H14/H18/H22/H24/H32, etc.

Thickness: 0.2-5.0mm

Width: 100-1700mm

Product Details

The primary raw material used is high-quality, environmentally friendly aluminum liquid from Guangyuan Zhongfu, which is produced using a short-process twin-roll casting technique to form casting coils. The casting coils are then subjected to multiple passes of cold rolling using a four-roll mill to produce coil materials that meet the specific requirements of end users. The cold rolling equipments are equipped with advanced thickness control systems and surface treatment facilities to ensure that each cold-rolled aluminum sheet meets strict thickness and surface quality requirements. We offer aluminum coils from the 1xxx, 3xxx, 5xxx, 6xxx and 8xxx series, with a thickness range of 0.2-5.0mm and a width range of 100-1700mm. Our monthly production capacity reaches 15,000 tons.

Aluminum Coils Parameter:

| Alloy | 1050/1060/1100 3003/3004/3005/3104/3105 5005/5052/5754/ 5083 6061/6082 8011 |

| Temper | O/H12/H14/H18/H22/H24/H32, etc. |

| Thickness | 0.2-5.0mm |

| Width | 100-1700mm |

| Surface | Mill Finish |

| Type | Cold rolled(CC) |

1 Series Aluminum Coil

1000 (brand) series aluminum alloy represents 1050, 1060, 1100. In all series, 1000 series belongs to the most aluminum series, purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively single, and its price is relatively cheap. It is currently one of the most commonly used series in the conventional industry. Most of the current circulation on the market is 1050 and 1060 series, 1000 series aluminum plate determine the minimum aluminum content of this series according to the last two Arabic numerals. Its characteristics are: good electrical conductivity, good corrosion resistance, good welding performance, low strength. In terms of use, it is relatively soft, mainly used to do decorative parts or interior parts, mostly used in the chemical industry and special purposes.

1 series Aluminum coil is a metal product of rolling and rolling corners. It is widely used in electronics, packaging, construction, machinery and other aspects. Most of the aluminum coils produced by our company are between 0.5 mm and 4 mm thick, and the width is generally from 500 mm to 2200 mm.

3 Series Aluminum Coil

3 series aluminum alloy is also known as aluminum manganese alloy, widely used as antirust aluminum alloy series. The strength of the 3 series aluminum alloy is high pure aluminum alloy. After cold work and annealing process, it has good plasticity, corrosion resistance and welding performance. It can be used in many industries, such as building decoration industry, electronic industry, automobile manufacturing and so on. We are aluminum products supplier and manufacturer, and have our advanced production lines and mature marketing system. We mainly concentrate on aluminum sheet/plate, aluminum circle/disc and aluminum coil, with the main brand 3003, 3004, 3005, 3104, 3005, 3105 for your reference.

3 series aluminum coil also known as heat treatment non-strengthening alloy with high plasticity, good welding performance. We can supply excellent aluminum coils with thicknesses between 0.5mm-4mm, 4.1-10.0mm and width ranging between 500-2200mm. It is mainly used in the manufacturing of automobile, aircraft fuel tank oil pipe, container tank, mechanical parts and other fields.

3003 aluminum coil has good anti-rust performance, excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is suitable for pipeline and tank anti-corrosion heat preservation, kitchenware, food and chemical products processing and storage devices, plate processing of various pressure vessels and pipes.

3004 aluminum coil is the best aluminum material in the three series. It is an alloy series aluminum coil. 3004 aluminum coil is higher than 3003 in hardness and price aspects, and the elongation is also higher than 3003. It commonly used in metal roof, metal plate strength, cans and other products.

3104 aluminum coil is a deformed aluminum alloy, tensile strength is greater than or equal to 275MPA and elongation can reach 20%. With good deep punching performance, it is suitable for pull-ring material, lamp cap material, shutter material, oxidizing material, color coated aluminum plate base and automobile fuel tank.

5 Series Aluminum Coil

5000 series aluminum alloy, also known as Al-Mg alloy, is mixed with magnesium. Characterized by low density, high tensile strength, high elongation and excellent corrosion resistance, it’s weldable and applied to a wide variety of purposes including pressure vessels, automotive, buildings, etc., especially suitable for marine environment. Its common types include 5005, 5052, 5083, 5754, etc.

5 Series Aluminum Coil Applications:

5005 aluminum coil: Storage tanks, chemical equipment, food processing equipment, roofing & siding materials, etc.

5052 aluminum coil: Pressure vessels, treadplate, marine components, chemical equipment, road & name signs, etc.

5754 aluminum coil: Ship building, food processing equipment, treadplate, vehicle bodies, fish industry equipment, welded chemical & nuclear structures, etc.

5083 aluminum coil: Rail cars, pressure vessels, vehicle bodies, ship building, mine cages & skips, tipper truck bodies, etc.

Supply Forms: 5005/5052/5754/5083 coil/sheet/circle

6 Series Aluminum Coil

The 6000 series aluminum alloy mainly contains two elements, magnesium and silicon, so it concentrates the advantages of the 4000 series and the 5000 series, and is a cold-treated aluminum forging product. Suitable for applications requiring high resistance to corrosion and oxidation. Good usability, excellent interface characteristics, easy coating, and good workability.

Features: Mainly contains magnesium and silicon. Mg2Si is the main strengthening phase and is currently the most widely used alloy. 6063, 6061 are used most, other 6082, 6160, 6125, 6262, 6060, 6005, 6463. 6063, 6060, and 6463 have relatively low strength in the 6 series. 6262, 6005, 6082, and 6061 have relatively high strength in the 6 series.

Medium strength, good corrosion resistance, good welding performance, good process performance (easy to extrude and form), good oxidation and coloring performance.

Application range: energy transfer tools (such as: car luggage racks, doors, windows, body, heat sinks, inter-box shells.

6082 Aluminum Alloy Coil: 6082 aluminium alloy is an alloy in the wrought aluminium-magnesium-silicon family (6000 or 6xxx series). It is one of the more popular alloys in its series (alongside alloys 6005, 6061, and 6063), although it is not strongly featured in ASTM (North American) standards. It is typically formed by extrusion and rolling, but as a wrought alloy it is not used in casting. It can also be forged and clad, but that is not common practice with this alloy. It cannot be work hardened, but is commonly heat treated to produce tempers with a higher strength but lower ductility.

6 Series Aluminum Coil Application

6082 aluminum alloy is a medium strength alloy with excellent corrosion resistance. 6082 aluminum alloy has the highest strength of the 6000 series alloy. Due to the higher strength of 6082 aluminum alloy it has replaced Alloy 6061 in many applications. 6082 aluminum alloy is typically used in highly stressed applications, Trusses, Bridges, Cranes, Transport applications, Ore Skips, Beer Barrels, Milk churns.

8 Series Aluminum Coil

The 8000 series includes 8011, 8090, 8091 and 8093. Lithium has a significantly lower density than aluminum because its solubility is also relatively high, and it can significantly reduce the density in a sufficient amount of aluminum alloys (usually about 10%, less than other aluminum alloys). Not only causes the alloy to increase its stiffness, but also responds to age hardening. In addition, the resistance to fatigue crack growth increases at intermediate pressure levels. This attractive combination of properties has led to great interest, especially for aerospace applications. These alloys have a high volume fraction of coherent, ordered LiAl 3 precipitation, which is responsible for these properties. Silicon strength: For example, the 8011 alloy is based on Al-Fe-Si, but more than 1% of the total alloying elements give a correspondingly higher advantage.

The 8000 series are alloyed with a variety of other elements such as iron and lithium. Generally, they are created for very specific purposes within specialist industries such as aerospace and engineering. They offer similar properties to the 1000 series but with higher strength and formability.

8 Series Aluminum Coil Characteristic:

Belongs to aluminium-lithium alloy, the main component is lithium, cause lithium is the lightest metal in nature, after adding lithium element to aluminum plate, it can guarantee the strength of aluminum plate while effectively reducing the proportion of aluminum plate.

8011 Aluminum Alloy Coil: 8011 aluminium alloy is a common aluminum foil alloy with iron and silicon as the main alloying elements. It has been widely used in sealing packing of cosmetic bottles, beverage bottles and air conditioning aluminum foil because of its good deep drawing performance and low earing rate.

Port: Qingdao port, Shanghai port, Dalian port and other main port in China

Container: 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) , loading 18-25 tons .

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) , loading 20-28 tons.